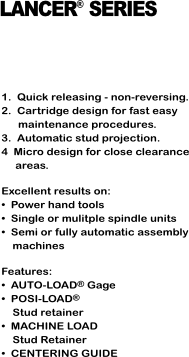

The Titan Tool Company has specialised in stud driving since 1920. Because of this experience, they have the knowledge to meet virtually any stud driving need -

The Titan Tool Company has specialised in stud driving since 1920. Because of this experience, they have the knowledge to meet virtually any stud driving need -

Quality is another benefit they have guaranteed for more than 75 years. Stud drivers for hand-

As sole distributors of Titan products in the UK, we carry a variety of items on our shelves. Please see below for a selection of the most popular items we hold. If the item you require is not on the list please contact our sales team for price and availability on 02392 371918 or sales@pdtools.co.uk. If you do not have a part number but have measurements or a description please contact our technical department who will be able to provide you with the required information 02392 371918 or at technical-

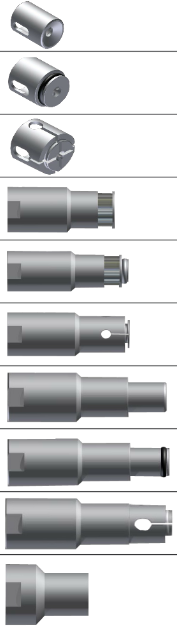

Centering Guide

• Use when studs are pre-

• Requires torque control in stud driver* or torque controlled power tool

Posi-

• For semi-

• Requires torque control in stud driver* or torque controlled power tool

• May also be used for machine loading of stud (Ex. -

ML Machine Load Stud Retainer

• For fully automatic pre-

• Requires torque control in stud driver* or torque controlled power tool

• NOT recommended for hand loading

#10 Gage

• For adjustable stud projection height

• Trips tool into “non-

• Not recommended when driving studs to shoulder or bottoming studs in hole

• Studs must be pre-

#10 AL Auto-

• For semi-

• Trips tool into “non-

• May also be used as stud retention device on torque controlled application with longer

studs (If so, gauge MUST NOT touch workpiece before required torque is reached.)

#10 ML Machine Load Gage

• For fully automatic pre-

from shuttle plate with ML gage provides superior concentricity of stud as workpiece is

approached.) Not recommended for semi-

• May be used as trip gage for automatic projection OR used only as stud retention

device on torque controlled application if stud length permits

#11 thru #15 Gages

• Use same as #10 Gage, but for increasingly longer stud projection requirements

#11 AL thru #15 AL Gages

• Use same as #10 AL Gauge, but for increasingly longer stud projection requirements

-

#11 thru #15 ML Gages

• Use same as #10 ML Gauge, but for increasingly longer stud projection requirements

-

#1 Open Gage

• Use same as #10 Gauge on studs with extremely short projection heights

CAUTION: O.D. of workpiece must be greater than 25/32” (19.8mm) when used on

Lancer-

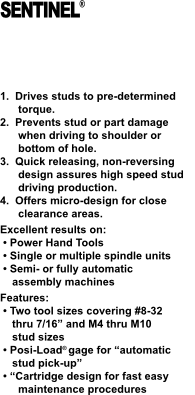

* TITAN SENTINEL has an adjustable torque clutch. LANCER does NOT.

MICRO-

STUD DRIVER

SERIES

MICRO-

STUD DRIVER

WITH TORQUE CONTROL